As part of the 2021 revamp of F1, one of the key cost savings being considered is the switch to a carefully selected number of spec parts. The list is quite short and for the large part will go unnoticed by the fans and teams. The tender for the gearbox cartridge has already been published by the FIA and another three tenders have recently been released for the brake system, brake material and wheels

Brake system

The brake system consists of the brake caliper, master cylinder and brake-by-wire (BBW) unit. As the brake discs, pads and pedals are in separate tenders, this is a neatly-contained package of parts for a supplier to provide.In terms of specification the current calipers are quite tightly constrained, being fixed to six pistons, aluminium lithium material and just two fasteners bolting the caliper to the suspension upright.

At present teams purchase their brake calipers and master cylinders. Brembo is the most widely-used supplier, others include Akebono (McLaren), 920e (Racing Point) and AP Racing. BBW unit supply is shrouded in confidentiality, but being a hydraulic control system they may be of the teams’ own designs, or perhaps produced in partnership with their braking suppliers.

Even with eight teams running the same supplier’s calipers, each individual team will run its own variation to suit their particular hose connections and cooling requirements. So the future supply of a spec caliper will reduce the options for teams, cutting costs at the same time and with little performance loss.

Some revised technical details are apparent in the tender. Firstly the material choice will switch from aluminium lithium to 2618 or an equivalent aluminium alloy, this will be a cost reducing change. However, with this change will be a loss in the stiffness of the component, which is a critical factor in the effectiveness of the caliper.

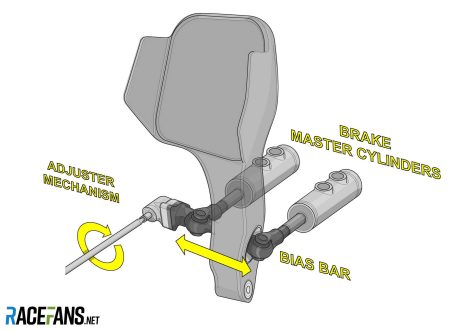

Driving brake fluid to the calipers is the job of the master cylinder. Currently F1 cars run dual master cylinders, with the pedal compressing two separate master cylinders (one each for the front and rear brakes) via a bias bar. With different master cylinder bore sizes and the geometry of the bias bar the pedal will send a proportionate amount of pressure to both the front and rear brakes.

Until 2014 the front-to-rear bias ratio could be tweaked by the driver using a cockpit adjuster which moved the bias bar on the pedal. Since then the rear braking has been taken care of by the BBW unit.

Advert | Become a RaceFans supporter and

With this system the rear master cylinder creates pressure, though in normal use it is not directed to the caliper, but to the BBW unit as an input for braking demand. The BBW then subtracts whatever regenerative braking is being applied by the ERS-K to keep a consistent braking effort on the rear brakes. If the BBW fails the master cylinder pressure is redirected to the rear brakes, to help stop the car in a balanced way.

With a spec brake pedal and master cylinder the usual variety of set-ups to suit each driver will be restricted. Teams are to propose their preferred sets up to the winning supplier and then a workable solution will be selected, with the FIA arbitrating where necessary. There will be losers in this regard as some drivers drive most confidently with specific brake set up, but this may be tune-able via the BBW.

As mentioned above, the current BBW unit manufacturers are unknown. The units are part of the hydraulic control system, so may use servo valves from Moog and braking components from the team’s brake supplier, assembled into a team designed manifold. Having a spec part here again may affect driver feel, as one of the issues in 2014 was the drivers getting used to the pedal feel from a dead end master cylinder circuit. Subsequent development by the teams and brake suppliers artificially recreated the feel with hydraulic accumulators along with carefully sized pistons and pipework.

Go ad-free for just £1 per month

>> Find out more and sign up

Brake material

Historically there are three suppliers of carbon brake material to F1: Brembo, Carbone Industrie and Hitco. The special brake material is expensive and time-consuming to manufacturer, hence the costs. Then the machining of the bulk material into the finished discs, with their 1,500 cooling holes, and the pads adds further expense. Currently the discs are 278mm in diameter and restricted in thickness to 32mm. While there can only be two brake pads per wheel, which can also be drilled for cooling between the main body of the pad and the area where the caliper piston presses on the pad.

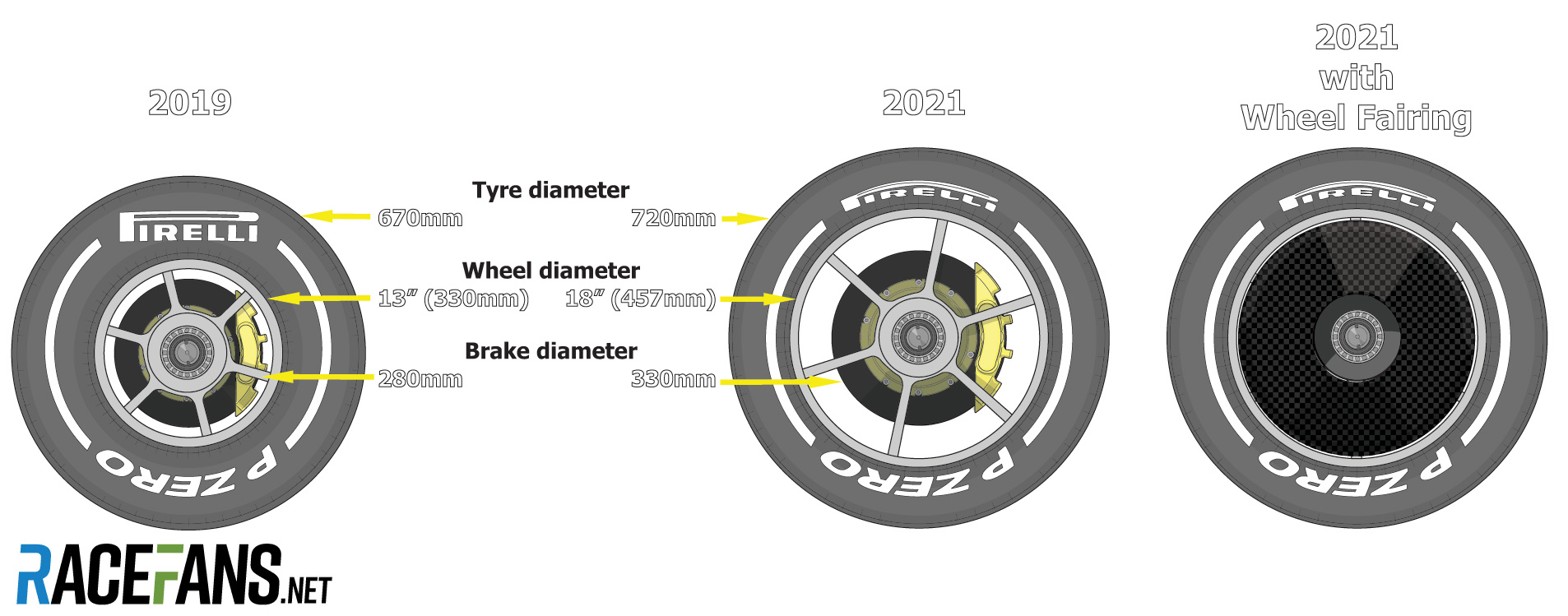

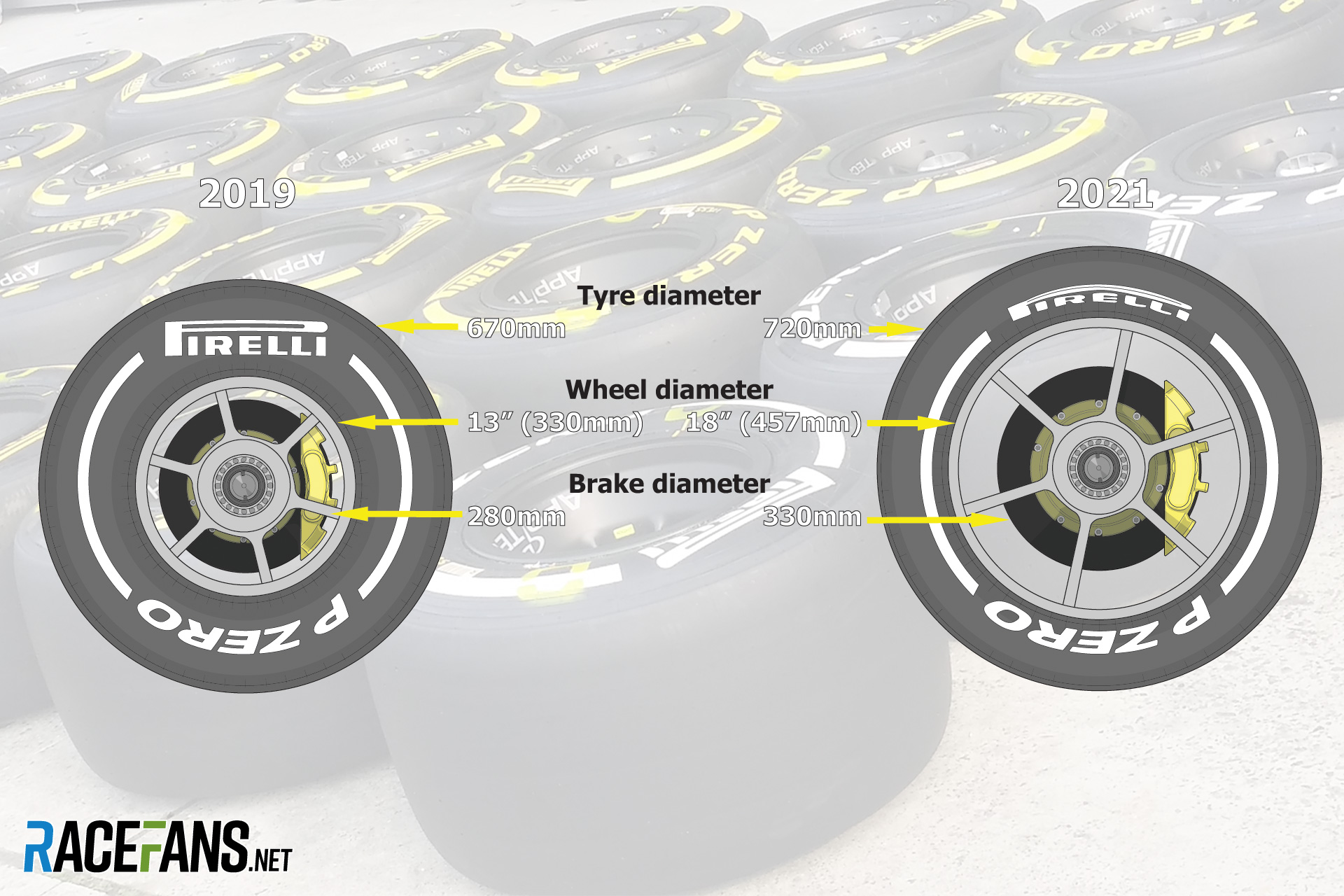

In the tender we learn that with the new larger wheel sizes will accommodate larger brakes so the disc will grow to 320mm or 330mm in diameter. The extreme amount of cooling holes in the current discs will be reduced, as they have grown from 100 holes in 2005 to some 1,500 today, so to cut costs the supplier can elect how many they feel is necessary within budget.

This could create a problem at circuits like Singapore which place a high demand on the brakes, so the supplier will have to offer two brake disc specifications; the cheaper, normal-duty disc with fewer holes, and for at least four circuits on the calendar a heavy-duty disc which is more expensive but provides greater cooling.

The pads must also a multi-directional design, so that just one part can be used on any of the front brake calipers. Additionally, the pad cannot have a drilled rear face.

For the rear brakes the tender is less prescriptive, as they are less stressed than the front brakes due to the braking effect of ERS. Already many teams run thinner rear brake discs and even four-piston rear calipers, as the ERS braking effect is so strong. The supplier will have to propose what diameter and thickness disc is suitable, with the benefit that the FIA are not asking for the braking set-up at the rear to be able to run with an ERS failure.

Advert | Become a RaceFans supporter and

Wheel

We already know that the wheels will be going to a larger diameter rim size, from the current 13 inches to 18, to make the cars look more like most other current road and race cars. F1’s distinctive ‘balloon’ tyres will disappear, but this is an overdue change.

Along with the spec Pirelli tyres, the wheels themselves will also be a spec part from 2021. The tender is asking for a supply of spec front and rear wheels for the entire grid. Current wheels are fixed in size, but there is an impact with this change, as different spoke design, heat transfer treatments and total weight do vary by team.

Current rules call for AZ70 or AZ80 Magnesium for the wheels, where as the spec wheel material choice is free. This might open up an opportunity for a cheaper wheel material and construction technique. It’s unlikely carbon fibre would be chosen as the spec material, as the cost of manufacture is high and the added cost of post-race inspection for damage would be far higher, especially considering the shorter tyre walls that could lead to rim damage over kerbs.

Any spoke design chosen for the wheel is likely to be inconsequential, as the wheels will be closed off with carbon fibre fairings as part of the aero changes for 2021. This spec fairing might be supplied by the successful wheel supplier, but not necessarily. Regardless the wheel design must accommodate the fairing being fixed to the wheel. So, the 2021 wheel fairings will spin with the wheel, not remain static as when these parts were previously seen in 2008-09.

The wheel supply must also incorporate the inflation valve and provision for one wheel nut. This nut will not be captive, as has been the trend in recent seasons. At pit stops this means the wheel nut will be held in the wheel gun socket and refitted to the new wheel. Both the wheel nut and wheel gun will be part of other spec part tenders.

Finally, the wheel must also provide for a new tyre temperature and pressure sensor (TTPS). This sensor will be detailed in a separate tender, and will be mandatory, even though already teams run homologated TTPS.

F1 technology

- Pictures: Alpine’s new front wing and more Suzuka updates

- Pictures: Red Bull bring first performance upgrade for RB20

- How teams have tweaked their cars to hit higher speeds in Jeddah

- ‘A horrible project’: Why duplicating Red Bull’s trend-setting suspension is so difficult

- Aston Martin, Mercedes, Haas and others describe extensive US GP updates

HansieSlim (@)

6th May 2019, 12:52

I wonder how much money the teams will save as a result of these changes. Does not seem to be an awful lot and also without any cap on spending I cannot see how this will really assist with both the financial and performance deficits between teams. The larger teams will simply shift resources to other areas that they can still influence.

Phylyp (@phylyp)

6th May 2019, 13:43

@hansieslim – I’d think the savings would be zero – any money saved would instead go towards the suspension – to give it a larger range of articulated motion, and to also help tune the car setup better. Today a fair amount of the setup is very dependent on tyre pressures, I think that will proportionally decrease, and will instead shift to the suspension.

BasCB (@bascb)

6th May 2019, 13:46

It mainly just cuts out areas where there is not deemed to be a lot of money can be gained currently anyway. But by having spec parts, you save the effort of having to TRY to find something, as well as the FIA (or rather competitors) having to LOOK for things on cars that might not be up to spec.

Also, with all of these, they will cost a lot less because a supplier can manufacture them in larger quantities, can have easier planning as well. And in the case of the wheels, it migh help eliminiate waste because in theory Pirelli can more easily prepare the tyres, since they don’t need to put them on the wheels of all the teams, since the wheels will be interchangeable. Could help make it easier to have extra sets available.

Another aspect, which certainly is important with the wheel nuts is safety – it is far easier to manage safety when these are to a clear and single spec and don’t change. It also means a pitstop will slow down a bit, since the guns won’t be as over the top engineered, the nuts are seperate parts, so have to be put on first etc. All of this will be more in the hands of the FIA.

BasCB (@bascb)

6th May 2019, 14:04

eh, right that should be “a lot of time” … but money can be spent studying it.

DAllein (@)

6th May 2019, 17:20

Exactly 0$, and actually they will spend more accommodating these changes.

Good work, FIA/Liberty!

F1oSaurus (@)

6th May 2019, 19:42

@dallein Wrong

pastaman (@)

6th May 2019, 13:15

Absolutely love these articles by Scarbs!

Jimmi Cynic (@jimmi-cynic)

6th May 2019, 22:40

Agree. Helps one realize that F1 isn’t just about driver-ego-bruising and Netflix drama-coaching.

Fer no.65 (@fer-no65)

6th May 2019, 13:20

Maybe I’m being to simplistic but we are going to bigger wheels but then the wheels will be covered like they were in 2009? Doesnt that defeat the point of trying to make the wheels look more like the ones found in road cars?

Christopher Rehn (@chrischrill)

6th May 2019, 13:29

It’s not only about the looks. It’s about road relevancy. Michelin amongst others wanted to provide 18 inch tyres to F1, but not 13 inch tyres. 18 inch would attract multiple tyre manufacturers, and that in turn can lead to a price drop due to increased competition to win the tender.

Pedro Andrade

6th May 2019, 13:45

@chrischrill: total ignorance on my part as I don’t understand the technical aspects very well, but how does the size change make the tyre more relevant to road cars? This is mentioned often, but I imagine that the differences in speed, car shape, track surfaces and others should be so different between a F1 car and a road car that having the tyre be of the same size should be pretty much irrelevant.

BasCB (@bascb)

6th May 2019, 13:48

It’s about the construction Pedro.

Tyres with huge (for modern standards) tyre walls behave quite differently than tyres on larger rims.

So on the one hand the construction has to be quite different (bespoke) for F1. And on the other hand the supplier has a tougher job because their huge experience from other tyres doesn’t quite apply to F1 tyres. That also means that what they learn from F1 is of less use to them as well.

Chaitanya

6th May 2019, 14:05

Chainbear has a great video on youtube explaining difference between current F1 tyres to the proposed larger diameter tyres.

anon

6th May 2019, 15:44

Pedro Andrade, to be honest, I am more doubtful of the road relevance of most racing tyres irrespective of the diameter – Michelin themselves have indicated that marketing and aesthetic choices have been a fairly significant factor in their push for 18 inch rims in F1 (particularly since the most common rim sizes are much smaller, with 14 to 16 inches being more common).

I recall hearing one tyre engineer at a major tyre manufacturing company state that, if anything, he thought that it was actually significantly harder to produce a tyre for a road going vehicle than it was for the race track. In the case of a race track, often the problem is fairly simple – it’s mainly about the peak grip the tyre generates. Wear, to some extent, is a bit of a factor, but even in endurance racing, most tyres don’t really need to last more than a few hundred miles at most.

By comparison, a road car has a more complex set of issues to address, and a number of problems which are not a factor for a racecar become more significant issues – for example, noise emissions isn’t really a concern on track, but the average consumer is going to have a much lower tolerance for the amount of noise they’re prepared to tolerate on a daily basis.

The average person expects those tyres to operate in a wide range of weather conditions, counterbalance issues such as longevity and rolling resistance against usable grip, noise, cost etc., not to mention the issue of interoperability – a tyre manufacturer often just has to consider one set of cars, or a fairly limited number of cars, when designing a car for a race track, whereas a road tyre is normally designed to accommodate a far wider range of vehicles.

Phylyp (@phylyp)

6th May 2019, 17:43

Good points, anon. It has often been said that racing tyres have little to no commonality with road tyres, and it looks like that will continue to be the case. At its essence, road tyres have roughly two orders of magnitude higher longevity than racing tyres, and unless that changes, it’s hard to see “road relevance” applicable for tyres.

Jimmi Cynic (@jimmi-cynic)

6th May 2019, 22:37

@phylyp: True, not much road relevance.

UNLESS… the FIA decides to specify only 3 sets of tyres per season. To aid F1’s computationally-challenged newbies – 3 power units and 3 sets of tyres per season.

With future rules filling out the trio of symmetry – 3 sets of brake pads, 3 helmet designs, 3 noses, 3 rear wings. Until finally, F1 becomes a 3-wheeled series. To attract new entrants, like Morgan, Vanderhall and Polaris.

Pedro Andrade

7th May 2019, 9:50

Thanks everyone for the nice discussion! I tend to agree with what anon said, it seems odd to me that just a difference in tyre size could be relevant to road car tyres when there are so many variables to consider in the construction of a road car tyre.

Matteo (@m-bagattini)

6th May 2019, 13:58

@fer-no65 this wheel fairing thing is new to me. It looks pretty ugly, like it was in F1 a few years ago. It’s a shame, since 18″ wheels with good rims sounded pretty cool to see.

Jeanrien (@jeanrien)

6th May 2019, 14:40

@m-bagattini they could certainly paint them as regular rims. Or include some leds to show the driver number or anything on the wheel…

I am not for it, but I am not deciding and it doesn’t sound impossible for liberty to follow that idea.

tony mansell

6th May 2019, 18:40

They are horrible but they are there to stop aero in the wheel shovelling out dirty air into the car behind. Close racing as a thing ceased to exist several years ago. Just watch stuff from the 80s and 90s and you have cars practically touching the car in front. Now they sling shot past using DRS from 50 yards away. This is an ugly but useful partial solution.

Antonius Rock (@antoniusrock)

6th May 2019, 14:27

Standard parts = slippery slope, brought about by the new owners push for ‘exciting races’ to generate more revenue.

F1 is supposed to be a prototype sport, ergo ANY standardisation means ultimately, fast Formula Fords.

Can’t see manufacturer money hanging around.

To whit standardisation = stagnation.

MagillaGorilla (@magillagorilla)

6th May 2019, 15:14

@antoniusrock how are things that are already fairly standard a slippery slope? I mean unless you’re coupling it with the other standard items that exist or come in the future, but the main pieces of the car that are not standard are still intended to be a such. It’s quite a stretch to claim “fast formula fords” especially with such black and white thinking.

Rhys Lloyd (@justrhysism)

7th May 2019, 5:39

Go on, switch off then.

LosD (@losd)

9th May 2019, 8:55

Without standardisation, F1 would have died many, many years ago.

NS Biker (@rekibsn)

6th May 2019, 15:58

One wonders if this philosophy had been in place in the early 60s, would we still be driving around with drum brakes.??

Likely that the main money saving aspect for the teams will be the reduced need for design and testing resources (aka people) for things like wheels, brakes, ERS control etc. Nuts I say.

The wheel covers are going to take some getting used to, but think of them as potential advertising space.

All well and good until someone tells the brake supplier, you need to build temperature sensitive high degradation brakes to spice up the show.

Something to look forward to is everyone having a realistic crack at getting a 13 inch coffee table center piece. Should be a whole bunch coming available in 2021.

Scarbs …. one of your best articles. absolutely FULL marks for this one. Thanks, you help (and we know it is hard) to make us all feel knowledgeable.

DAllein (@)

6th May 2019, 17:23

The more we learn about 2021 the more it gets clearer F1 will die, unless decision-makers reconsider killing it in the last minute.

I am already content with 2020 being my last season. 26-27 years… it was a good ride.

Yaru

6th May 2019, 18:45

See ya.

DAllein (@)

7th May 2019, 22:25

Really smart! Keep it up!

Rhys Lloyd (@justrhysism)

7th May 2019, 5:40

@dallein Don’t let the door hit you on the way out.

DAllein (@)

7th May 2019, 22:24

Go to…

Mashiat (@mashiat)

7th May 2019, 8:18

@dallein Talk about dramatic…

RB13

7th May 2019, 10:14

@dallein yes because closer, less aero dependant racing with less financial advantage amongst the field sounds awful.

Bye then!

DAllein (@)

7th May 2019, 22:24

Stock racing is not the same as “less aero dependent”.

Wake up

BJ (@beejis60)

6th May 2019, 17:54

I thought all teams ran monobloc calipers (machined all from one piece). Switching to fully aluminum monoblocs will likely increase flex but maybe building larger units will help to increase stiffness. I’m pretty excited to see what will be offered and hope we can see some close-up images in 2021+.

DaveW (@dmw)

6th May 2019, 18:24

I don’t see the cost or performance-limitation reason for wheel covers. Why is this being reintroduced? We had them before, and they got banned for cost and performance limiting reasons. Indycars had them too and they got banned.

Robert S

6th May 2019, 20:46

Wheel covers are, as Scarbs point out, for aero-reasons. Most likely part of the effort to reduce outwash and improve overtaking ability.

Racingdave

6th May 2019, 19:05

Could we see longer braking distances increasing overtaking possibilities?

John S

6th May 2019, 21:30

Why? if using standard parts is cheaper, why cant one of the race teams just buy the same parts as someone else?

I think the solution is to say no exclusivity for these parts, so all teams can either buy off the shelf, or choose to make a custom. So, in summary, I think FIA should just say no exclusivity for brake parts, instead of requiring standard parts.

Rhys Lloyd (@justrhysism)

7th May 2019, 5:42

Umm… I think that’s how it is currently.

mmertens (@mmertens)

7th May 2019, 2:05

Hi Scarbs, great read as always. It was great to see the impacts on brakes rims and tires, but what about the impact on suspension design / construction? Nowadays the 13” tires have a bit of suspension role in kerbs and general track imperfections, making possible to run with really stiff suspension setups. How do you think the impact will be now? I assume the suspension / shocks will need to cope with a lot more than nowadays right? Could you foresee what would be an probable solution for this? That will be really appreciated! Great article!

Pjotr (@pietkoster)

7th May 2019, 9:42

Now this is again killing for F1 imo. Two ways to overtake. First is pure speed and the other is outbraking your opponent. Now the braking will be the same for everybody, at the same speeds and at the same moments. Or do they expect a faster car has to break earlier than a slower car so this equalises the difference in speed? Then first check this out before implementing otherwise F1 will get more boring than it already is.

Clay_T

7th May 2019, 18:32

I imagine available brake force will still exceed available traction, just as it does now. The car with the best balance and down force will still win in the braking zone.

Pjotr (@pietkoster)

9th May 2019, 12:23

That is what I ment. A faster car needs to brake earlier than a slower car just to save the worst in F1, the pirelli’s.

RaptorHunter

7th May 2019, 22:13

I wonder what will happen when one of the suppliers, delivers a substandard product after wining a bid.